Weir Minerals Study Highlights Energy Saving Possibilities in Comminution

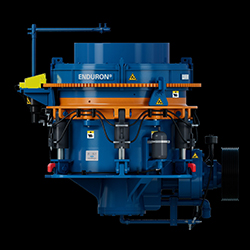

The Weir Group PLC has completed a study that highlights a significant opportunity to reduce energy use and emissions in comminution, the rock crushing process that is key to minerals extraction, and that consumes around 3% of the world’s electrical power each year1. The study shows that replacing conventional technology with innovative new solutions can cut energy use by 40% while also avoiding 50% of CO2e emissions.

Unveiling the study during the panel discussion at COP28, Paula Cousins, Chief Strategy and Sustainability Officer at Weir said: “The need for technology solutions in mining is compelling – the world needs more transition metals to achieve net zero, but the mining industry needs to extract these using significantly less energy and water. Our new, externally assured study highlights the potential for energy savings of 40% and for 50% of CO2e emissions to be avoided in comminution, the most energy intensive stage of mining processes. By adopting a systems-based approach to technology collaborations, we can help the mining industry scale up and clean up at the same time.”.

Given its energy intensity, the decarbonisation opportunities in comminution are significant, with the basic comminution process not having changed significantly for many decades. Weir says it is collaborating with customers and other partners to redefine the process, developing innovative combinations of proven technologies to make significant improvements to efficiency and environmental performance.

For more information

Categories: Mineral - Processing Equipment Mineral - Processing Services

2023-12-06 | Weir | United Kingdom | Views 1666